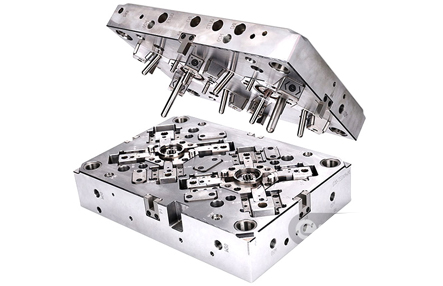

Sri Lakshmi Venkateshwara Engineering Works are highly specialized moulds used in the pressure die casting process, where molten metal is injected into a mould cavity under high pressure to produce precision metal parts. These moulds are primarily used for manufacturing parts from non-ferrous metals such as aluminum, zinc, and magnesium. Sri Lakshmi Venkateshwara Engineering Works designs and manufactures high-quality pressure die cast moulds that ensure superior dimensional accuracy, durability, and efficient production. Our moulds are built to withstand the intense pressures and temperatures involved in the casting process, ensuring long-lasting performance and reduced cycle times.

Pressure die cast moulds are designed for exacting accuracy and tight tolerances, ensuring that each part produced meets the highest standards of quality with minimal defects.

Constructed from premium high-strength steel, our moulds are built to endure extreme pressure and are capable of handling numerous production cycles, providing lasting reliability.

The innovative design of our moulds minimizes cycle times, enabling quicker production and maximizing throughput for increased manufacturing efficiency.

By minimizing the need for constant repairs and maintenance, our pressure die cast moulds help reduce operational costs, delivering greater value and lowering overall production expenses.

Our moulds are versatile, capable of working with various non-ferrous metals and accommodating diverse design specifications, making them suitable for a broad spectrum of industries.

Offers customizable pressure die cast moulds, tailored to each project’s exact needs, ensuring they perform optimally and meet unique product requirements.

With advanced mould design, we ensure that the casted parts have a flawless, smooth surface finish, elevating both the functional and aesthetic qualities of the final product.

Our pressure die cast moulds are engineered for longevity and reliability, requiring minimal maintenance while maintaining high performance throughout the production process.

At SLV, we thrive on the energy of driven individuals. If you’re eager to make a meaningful impact and grow alongside a vibrant community, we’d love to have you on board.