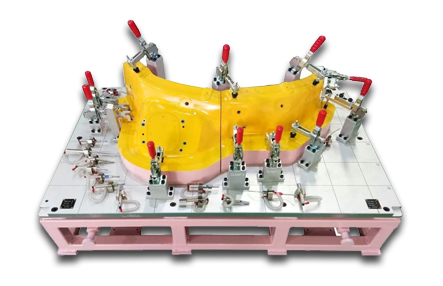

Checking fixtures by Sri Lakshmi Venkateshwara Engineering Works are highly accurate and reliable tools used in the manufacturing process to inspect the dimensions and quality of parts. These fixtures are designed to hold parts securely in place while ensuring that they confirm to specific standards or design specifications. We specialize in providing custom checking fixtures tailored to meet the precise inspection needs of industries such as automotive, aerospace, and electronics. Our checking fixtures ensure that every part is measured and verified for quality, reducing the risk of defects and ensuring that only parts meeting the required specifications are passed on to the next production stage.

Our checking fixtures provide highly accurate measurements, ensuring that parts meet exact specifications and preventing defects from progressing in the production line.

Built with premium materials, our checking fixtures are robust and designed for long-lasting performance, even under heavy use.

The fixtures help maintain high standards of quality control, allowing manufacturers to catch errors early in the process, reducing rework and scrap.

Sri Lakshmi Venkateshwara Engineering Works offers bespoke checking fixtures designed to fit your specific part and inspection needs, ensuring optimum results.

With easy-to-use features and quick setup, our checking fixtures reduce inspection time, improving overall production efficiency.

By identifying defects early in the process, our checking fixtures help lower the cost of rework and prevent expensive product failures.

Our checking fixtures are adaptable to a wide range of parts and industries, from automotive to aerospace, ensuring they meet various inspection criteria.

With stable and repeatable measurements, our checking fixtures ensure consistent quality throughout the production process, providing reliable results every time.

At SLV, we thrive on the energy of driven individuals. If you’re eager to make a meaningful impact and grow alongside a vibrant community, we’d love to have you on board.