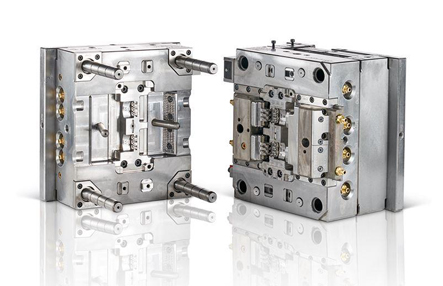

Customized mould bases from Sri Lakshmi Venkateshwara Engineering Works are tailor-made components used in the manufacturing of injection moulds, die-casting moulds, or other types of industrial moulds. These bases provide the structural foundation for the mould, ensuring precision and stability during the moulding process. By customizing the size, shape, and material of the mould base, Sri Lakshmi Venkateshwara Engineering Works helps manufacturers meet the specific requirements of a project, optimizing the mould's efficiency, durability, and performance. Customized mould bases are integral to producing high-quality products in industries such as automotive, electronics, and plastic manufacturing.

Customized mould bases are designed specifically for the unique needs of each project, ensuring a perfect fit for the mould's functionality.

With exact specifications, these mould bases offer high precision, reducing errors and improving the quality of the final product.

Custom moulds can be optimized for quicker production times, enhancing overall manufacturing efficiency.

Made from high-strength materials, customized mould bases provide long-lasting durability, reducing wear and tear during the moulding process.

Though initially more expensive, customized mould bases can reduce long-term costs by increasing the lifespan of the mould and minimizing the need for repairs.

Custom bases are designed to work seamlessly with specific mould designs, improving compatibility and reducing the chance of operational issues.

Mould bases can be customized with cooling channels, mounting holes, and other features that cater to specialized moulding needs.

By designing the mould base to meet the specific requirements of the mould, maintenance becomes easier, faster, and less frequent, leading to lower operational costs.

At SLV, we thrive on the energy of driven individuals. If you’re eager to make a meaningful impact and grow alongside a vibrant community, we’d love to have you on board.